We are officially back to same-day shipping. Thank you for your patience and understanding.

We are officially back to same-day shipping. Thank you for your patience and understanding.

- PARKER® PRODUCTS

- PARKER® STANDARD MOLYTHANE LOADED LIP SEAL POLYPAKS®

- PARKER® DEEP MOLYTHANE LOADED LIP SEAL POLYPAKS®

- PARKER® BEVELED LIP MOLYTHANE LOADED LIP SEAL POLYPAKS®

- PARKER® MOLYTHANE PIP(PRESSURE INVERTING PEDESTAL) RING

- PARKER® STANDARD MOLYTHANE UR NON-SYMMETRICAL ROD U-CUP

- PARKER® HI-TEMPERATURE DOUBLE LIP 4300 BT ROD U-CUPS

- PARKER® SYMMETRICAL MOLYTHANE US ROD or PISTON U-CUPS

- PARKER® STANDARD MOLYTHANE NON-SYMMETRICAL PISTON U-CUP

- PARKER® PSP STYLE 2Pc URETHANE/NBR PISTON SEAL ASSEMBLY

- PARKER® PSP-A 2Pc URETHANE/NBR PISTON SEAL ASSEMBLY

- PARKER® STANDARD MOLYTHANE CS PISTON CUP

- PARKER® THIN LIP MOLYTHANE CT PISTON CUP

- PARKER® STANDARD MOLYTHANE MODULAR U-CUP BACK UPS

- SEAL KITS & REPLACEMENT PARTS

- BUSH HOG® REPLACEMENT SEAL KITS & COMPONENTS

- ATLAS® REPLACEMENT SEAL KITS & COMPONENTS

- BARKO® REPLACEMENT SEAL KITS & COMPONENTS

- BLACKHAWK® REPLACEMENT SEAL KITS & COMPONENTS

- BOBCAT® REPLACEMENT SEAL KITS & COMPONENTS

- CASE® REPLACEMENT SEAL KITS & COMPONENTS

- CAT® REPLACEMENT SEAL KITS & COMPONENTS

- CHARLYNN® REPLACEMENT SEAL KITS & COMPONENTS

- CLARK® REPLACEMENT SEAL KITS & COMPONENTS

- COMMERCIAL®PARKER REPLACEMENT SEAL KITS & COMPONENTS

- COPELAND® REPLACEMENT SEAL KITS & COMPONENTS

- CORMACH® REPLACEMENT SEAL KITS & COMPONENTS

- CUSTOM HOIST® REPLACEMENT SEAL KITS & COMPONENTS

- DEMPSTER® REPLACEMENT SEAL KITS & COMPONENTS

- DOOSAN® REPLACEMENT SEAL KITS & COMPONENTS

- ENERGY® REPLACEMENT SEAL KITS & COMPONENTS

- ENERPAC® REPLACEMENT SEAL KITS & COMPONENTS

- ESCO® REPLACEMENT SEAL KITS & COMPONENTS

- EUCLID® REPLACEMENT SEAL KITS & COMPONENTS

- FASSI® REPLACEMENT SEAL KITS & COMPONENTS

- FIAT ALLIS® REPLACEMENT SEAL KITS & COMPONENTS

- FORD® REPLACEMENT SEAL KITS & COMPONENTS

- GALBREATH® REPLACEMENT SEAL KITS & COMPONENTS

- HEIL® REPLACEMENT SEAL KITS & COMPONENTS

- HITACHI® REPLACEMENT SEAL KITS & COMPONENTS

- HUSKY® REPLACEMENT SEAL KITS & COMPONENTS

- HYDRO-LINE® REPLACEMENT SEAL KITS & COMPONENTS

- HYSTER® REPLACEMENT SEAL KITS & COMPONENTS

- INGERSOLL-RAND® REPLACEMENT SEAL KITS & COMPONENTS

- INTL HARVESTER® REPLACEMENT SEAL KITS & COMPONENTS

- IOWA MOLD® REPLACEMENT SEAL KITS & COMPONENTS

- JCB® REPLACEMENT SEAL KITS & COMPONENTS

- JLG® REPLACEMENT SEAL KITS & COMPONENTS

- JOHN DEERE® REPLACEMENT SEAL KITS & COMPONENTS

- KALMAR® REPLACEMENT SEAL KITS & COMPONENTS

- KOBELCO® REPLACEMENT SEAL KITS & COMPONENTS

- KOMATSU® REPLACEMENT SEAL KITS & COMPONENTS

- KUBOTA® REPLACEMENT SEAL KITS & COMPONENTS

- LABOUNTY® REPLACEMENT SEAL KITS & COMPONENTS

- Leeboy® REPLACEMENT SEAL KITS & COMPONENTS

- LEACH® REPLACEMENT SEAL KITS & COMPONENTS

- LIEBHERR® REPLACEMENT SEAL KITS & COMPONENTS

- LINKBELT® REPLACEMENT SEAL KITS & COMPONENTS

- LOADMASTER® REPLACEMENT SEAL KITS & COMPONENTS

- LOGHOG® REPLACEMENT SEAL KITS & COMPONENTS

- MAILHOT® REPLACEMENT SEAL KITS & COMPONENTS

- WESTERN®/MEYER® REPL SNOWPLOW KITS & COMPONENTS

- MILLER® REPLACEMENT SEAL KITS & COMPONENTS

- MONARCH® REPLACEMENT SEAL KITS & COMPONENTS

- NEW HOLLAND® REPLACEMENT SEAL KITS & COMPONENTS

- NISSAN® REPLACEMENT SEAL KITS & COMPONENTS

- NORGREN® REPLACEMENT SEAL KITS & COMPONENTS

- PARKER® REPLACEMENT SEAL KITS & COMPONENTS

- PETTIBONE®REPLACEMENT SEAL KITS & COMPONENTS

- POWERTRAIN® REPLACEMENT SEAL KITS & COMPONENTS

- PRENTICE® REPLACEMENT SEAL KITS & COMPONENTS

- REXROTH® REPLACEMENT SEAL KITS & COMPONENTS

- SAMSUNG® REPLACEMENT SEAL KITS & COMPONENTS

- SHEFFER® REPLACEMENT SEAL KITS & COMPONENTS

- TAYLOR-DUNN® REPLACEMENT SEAL KITS & COMPONENTS

- TEREX® REPLACEMENT SEAL KITS & COMPONENTS

- TOWMOTOR® REPLACEMENT SEAL KITS & COMPONENTS

- TIMBERPRO® REPLACEMENT SEAL KITS & COMPONENTS

- TOYOTA® REPLACEMENT SEAL KITS & COMPONENTS

- TROJAN® REPLACEMENT SEAL KITS & COMPONENTS

- US TRUCK CRANE® REPLACEMENT SEAL KITS & COMPONENTS

- VERSALIFT® REPLACEMENT SEAL KITS & COMPONENTS

- VOLVO® REPLACEMENT SEAL KITS & COMPONENTS

- WALTCO® REPLACEMENT SEAL KITS & COMPONENTS

- WESTERN® REPLACEMENT SEAL KITS & COMPONENTS

- U CUPS

- POLYPAK®/STANDARD O-RING LOADED LIP SEAL - INCH

- POLYPAK®/ DEEP O-RING LOADED LIP SEAL - INCH

- POLYPAK®/BEVELED O-RING LOADED LIP SEAL - INCH

- PR - PIP RING (PRESSURE INVERTING PEDESTAL RING) - INCH

- DZ - DEEP Z ROD SEAL - INCH

- UNRR - POLYURETHANE RIBBED ROD SEAL - INCH

- UNRR - POLYURETHANE RIBBED ROD SEAL-METRIC

- BS - DOUBLE LIP URETHANE ROD SEAL - INCH

- BS - DOUBLE LIP URETHANE ROD SEAL - METRIC

- MLLB - BEVELED O-RING LOADED LIP SEAL - METRIC

- BSLL - DOUBLE LIP ORING LOADED URETHANE ROD SEAL - INCH

- BS-B - URETHANE DOUBLE LIP ROD SEAL w/POM BACKUP - INCH

- BS-B -URETHANE DBL LIP ROD SEAL w/POM BU-METRIC

- BT - 4300® HIGH TEMP DOUBLE LIP ROD U-CUP - INCH

- BD - DOUBLE LIP O-RING LOADED ROD SEAL w/BACKUP - INCH

- BD - DOUBLE LIP O-RING LOADED ROD SEAL w/BACKUP -METRIC

- UNR - URETHANE ASYMMETRICAL ROD SEAL - INCH

- MA30 - URETHANE ASYMMETRICAL ROD SEAL - METRIC

- MA30B-URETHANE ROD SEAL w/NYLON BACKUP - METRIC

- MA35 - URETHANE SYMMETRICAL DOUBLE LIP ROD SEAL -METRIC

- C1 - NITRILE ASYMMETRICAL ROD U-CUP - METRIC

- MURH - NITRILE ASYMMETRICAL ROD U-CUP - METRIC

- MA24 - NITRILE ASYMMETRICAL ROD U-CUP - METRIC

- US- URETHANE SYMMETRICAL ROD or PISTON U-CUP - INCH

- MA25 - URETHANE SYMMETRICAL ROD/PISTON U-CUP - METRIC

- 8400 - NITRILE SYMMETRICAL U-CUP - INCH

- 6226 - NITRILE SYMMETRICAL (AN) U-CUP - INCH

- MA21 - NITRILE SYMMETRICAL PISTON or ROD U-CUP - METRIC

- MA22 - NITRILE SYMMETRICAL PISTON or ROD U-CUP - METRIC

- UCH - NITRILE NON-STANDARD HOMOGENEOUS U-CUP - INCH

- UCF - FABRIC REINFORCED NITRILE U-CUP - INCH

- UCL - LEATHER U-CUP w/NITRILE FILLER - INCH

- UNP - URETHANE ASYMMETRICAL PISTON U-CUP - INCH

- UNP - AN - THIN LIP URETHANE PISTON U-CUP - INCH

- MA28B/UNP Piston U-CUP w/OD BACKUP INCH & METRIC

- MA28 - URETHANE ASYMMETRICAL PISTON U-CUP-METRIC

- BP - DOUBLE LIP ORING LOADED URETHANE PISTON SEAL -INCH

- MA20 - NITRILE U-CUP w/STEPPED NYLON HEEL - METRIC

- RSE- URE PISTON U-CUP w/STEPPED BACKUP/BEARING- Metric

- C2 - NITRILE ASYMMETRICAL PISTON U-CUP - METRIC

- MUPH - NITRILE ASYMMETRICAL PISTON U-CUP - METRIC

- MA23 - NITRILE ASYMMETRICAL PISTON U-CUP - METRIC

- OUY - NITRILE PISTON U-CUP w/POM BACKUP - METRIC

- W1-3PC NBR/POM/TFE HGH PRESSURE POWERWASHER SEAL-METRIC

- W2 - 1PC NBR/FAB LOW PRESSURE POWERWASHER SEAL - METRIC

- W3 - 2 PC LOW PRESSURE POWERWASHER SEAL - METRIC

- ROD SEALS / BUFFER RINGS

- TR0 - 3PC NITRILE ROD T-SEAL w/NYLON BACKUPS- INCH

- TDI - Hunger® 2pc Urethane/PTFE Rod Seal - Metric

- AS7 - 2 PC DOUBLE ACTING BTFE/NBR ROD SEAL

- CAT® 2 PC REPL STEPPED BTFE/NBR ROD BUFFER SEAL - INCH

- AS2 - 2 PC STEPPED BTFE/NBR ROD BUFFER SEAL - INCH

- AS2 - 2 PC STEPPED BTFE/NBR ROD BUFFER SEAL - METRIC

- CAT®/CASE® Repl 1pc PU or NBR BUFFER RING - INCH

- MBRU - 1 PC RECTANGULAR URETHANE BUFFER RING - METRIC

- CBR/CTB - CAT®/CASE® U-CUP BUFFER RING - INCH

- MBR - URETHANE U-CUP STYLE BUFFER RING - METRIC

- BU - 2PC URETHANE/POM ROD BUFFER SEAL W/BACKUP - METRIC

- SM - NITRILE/POM/NYLON 3 PC RIBBED ROD SEAL - METRIC

- MD - NITRILE ROD SQUEEZE SEAL w/POM BACKUP - METRIC

- S8 - 2 PC BONDED ROD SQUEEZE SEAL - METRIC

- WIPERS

- 940 - URETHANE AN STYLE ROD WIPER - INCH

- 940 AN TYPE NON-STANDARD URETHANE ROD WIPER - INCH

- U - URETHANE UNIVERSAL "D" STANDARD ROD WIPER - INCH

- NON-STANDARD URETHANE UNIVERSAL "D" ROD WIPER - INCH

- U - NBR UNIVERSAL "D" STANDARD WIPER CORD - INCH

- A40 - NITRILE & URETHANE STANDARD ROD WIPER-METRIC

- U-R - URETHANE "D" ROD WIPER w/ RIBBED HEEL -INCH

- 842 - URETHANE UMBRELLA ROD WIPER - INCH & METRIC

- 842 - URETHANE UMBRELLA TOP ROD WIPER - METRIC

- A37 - JIS URETHANE KWI ROD WIPER - METRIC

- ENERPAC® REPLACEMENT URETHANE ASC STYLE WIPER

- 33 - RECTANGULAR BASE NBR SINGLE LIP ROD WIPER - INCH

- A39 - THIN WALL NITRILE SINGLE LIP ROD WIPER - METRIC

- NW - MOLY/NYLON ROD WIPER/SCRAPER - INCH

- NW - MOLY/NYLON ROD WIPER/SCRAPER - METRIC

- K - DOUBLE LIP URETHANE ANGLED BASE ROD WIPER - INCH

- K - DOUBLE LIP NITRILE WIPER CORD - INCH

- KB - SINGLE LIP URETHANE ROD WIPER - INCH & METRIC

- 7580 - "H" STYLE DOUBLE LIP NITRILE ROD WIPER - INCH

- H - "H" STYLE DOUBLE LIP URETHANE ROD WIPER - INCH

- H -SPECIAL SIZE HIGH LIP URETHANE "H" STYLE ROD WIPER

- 8600 - "H" STYLE DOUBLE LIP NITRILE ROD WIPER - INCH

- AY - "H" STYLE DOUBLE LIP URETHANE ROD WIPER - METRIC

- SDR - "H" STYLE DOUBLE LIP NITRILE ROD WIPER - METRIC

- ORK - CASCADE® REPLACEMENT URETHANE ROD WIPER - INCH

- OUTSIDE DIAMETER LIP URETHANE BORE WIPER

- ASC - LIGHT DUTY NITRILE OR URETHANE ROD WIPER - INCH

- A41- SINGLE LIP URE/NBR STEPPED ROD WIPER - Metric

- DA17 - DOUBLE LIP STEPPED NITRILE ROD WIPER - METRIC

- DA24 - DOUBLE ACTING DOUBLE LIP URETHANE WIPER - METRIC

- S34 - SEAL-GUARD® 2 PC BRONZE/NBR WIPER/SCRAPER - INCH

- 504 - METAL ENCASED BRONZE/STEEL/NBR ROD SCRAPER -INCH

- MS28776 - AN STYLE 2 PC METAL/NBR WIPER/SCRAPER- INCH

- ME - METAL ENCASED NITRILE or URETHANE ROD WIPER - INCH

- AMJ - METAL ENCASED URETHANE ROD WIPER - METRIC

- CAT® REPL METAL ENCASED DBL LIP URE ROD WIPER - INCH

- AMH - DBL LIP METAL ENCASED URETHANE ROD WIPER - METRIC

- AM43 - METAL ENCASED NITRILE ROD WIPER - METRIC

- AM44 - METAL ENCASED URETHANE ROD WIPER - METRIC

- AM46 - METAL ENCASED URETHANE LINK PIN WIPER - METRIC

- AM47 - METAL ENCASED NITRILE ROD LINK PIN WIPER - METRI

- AM48 - METAL ENCASED URETHANE LINK PIN WIPER - METRIC

- TW100 - 2PC BTFE/NBR SINGLE LIP SCRAPER/WIPER - METRIC

- TW500 - 2PC BTFE/NBR DOUBLE LIP SCRAPER/WIPER - METRIC

- PISTON SEALS

- PR - CAST IRON METAL PISTON RINGS - INCH

- UP - STEEL w/TFE SEAL & WEARBANDS UNITIZED PISTON SEAL

- 12 - 1PC 2 DURO URETHANE UNIRING PISTON SEAL - INCH

- AS700 - 2 PC RECTANGULAR GTFE/NBR PISTON SEAL - INCH

- AS800 - 2 PC TFE/NBR PISTON SEAL - INCH

- AS800P - 2 PC SQUARE URETHANE/NBR PISTON SEAL - INCH

- AS800B - 2 PC BTFE/NBR PISTON SEAL - INCH

- AS900 - 2 PC RECTANGULAR GTFE/NBR PISTON SEAL - INCH

- AS900B - 2 PC RECTANGULAR BTFE/NBR PISTON SEAL - INCH

- AS9 - SPECIAL SIZE 2 PC CTFE/NBR PISTON SEAL - INCH

- AS980 - CAT® REPL 2 PC GTFE/NBR HEAVY DUTY TFE - INCH

- AS2 -2 PC STEPPED BTFE/NBR PISTON BUFFER SEAL - METRIC

- AS2 - 2 PC STEPPED BTFE/NBR PISTON BUFFER SEAL - INCH

- AS7 - 2 PC BTFE/NBR HEAVY DUTY PISTON SEAL - INCH

- AS7 - 2 PC BTFE/NBR HEAVY DUTY PISTON SEAL - METRIC

- AS990 - 2 PC RECTANGULAR BTFE/NBR PISTON SEAL - METRIC

- AS600 - 2 PC RECTANGULAR HYTREL®/NBR PISTON SEAL - INCH

- PSP - 2 PC RECTANGULAR URE®/NBR PISTON SEAL - INCH

- PSP-A 2 PC NEW STYLE URE®/NBR PISTON SEAL - INCH

- CP - 2 PC RECTANGULAR URE®/NBR PISTON CROWN SEAL - INCH

- AS5/6/PSP-2 PC RECTANGULAR PU®/NBR PISTON SEAL - METRIC

- AS4 - 2 PC URETHANE/NBR PISTON SEAL - METRIC

- NO - 2PC FAB/NBR PISTON SEAL w/NYLON BACK UP - METRIC

- 714 - 2 PC STEPCUT NYLON PISTON SEAL w/SQR ENGZR - INCH

- OK - 2 PC STEPCUT NYLON PISTON SEAL w/SQR ENGZR -METRIC

- 914 - 2 PC STEPCUT NYLON PISTON SEAL w/OVAL ENGZR -INCH

- CAT® 2PC REP NYLON PISTON SEAL w/OVAL NBR EXPNDR - INCH

- CAT® 2PC REP NYLON PISTON SEAL w/OVAL NBR EXPNDR - MM

- TP0 - 3 PC NITRLIE PISTON T-SEAL w/NYLON BACKUPS- INCH

- TPT - WIDE BASE 3 PC NITRLIE PISTON T-SEAL - INCH

- M4 - 3PC FAB/NBR/NYLON PISTON VEE SET SEAL - METRIC

- AS880 - 3PC GTFE/NBR PISTON SEAL w/2 O-RINGS - INCH

- DS - 3PC NBR w/POM BEARINGS DELTA PISTON SEAL - INCH

- DSM - 3PC NBR w/POM BEARINGS DELTA PISTON SEAL - METRIC

- MDL - 3PC DOUBLE ACTING NBR/POM PISTON SEAL - METRIC

- ASQ - 3 PC BTFE/QUAD W/ORING PISTON SEAL W/ORING - INCH

- ASQ - 3 PC BTFE/QUAD W/ORING PISTON SEAL W/ORING-METRIC

- ASQ5 - 4PC BTFE/QUAD PISTON SEAL w/ 2 NBR EXPANDERS

- 4PE/4PV - 4 PC BTFE or URE/NBR/NYLON PISTON SEAL - INCH

- 4PT - 4 PC BTFE/NBR/NYLON CAT®TYPE PISTON SEAL - INCH

- 4PMM - 4 PC BTFE/NBR/NYLON PISTON SEAL - METRIC

- DAS - 5 PC NITRILE/NYLON/POM PISTON SEAL - INCH

- DAS - 5 PC NITRILE/NYLON/POM PISTON SEAL - METRIC

- MHM - JCB® REPL 5 PC SQUARE BACK PISTON SEAL - METRIC

- DSM - 5 PC NITRILE/NYLON/POM PISTON SEAL - METRIC

- GD1KK - 6PC NITRILE/NYLON/POM PISTON SEAL - METRIC

- PISTON CUPS

- DR - SINGLE ACTING FABRIC/NITRILE PISTON CUP - INCH

- SC - SINGLE ACTING HOMOGENOUS NITRILE PISTON CUP - INCH

- CS - SINGLE ACTING URETHANE PISTON CUP - INCH

- CT - SINGLE ACTING THIN WALL URETHANE PISTON CUP - INCH

- MIL - Miller A®, JW® & HW® REPL PISTON CUP - INCH-INCH

- DK - DOUBLE ACTING NBR/STEEL PISTON CUP - INCH

- DE-SNGL ACTING NBR/STEEL PISTON CUP w/CUSHION

- DK - DOUBLE ACTING NBR/STEEL PISTON CUP - METRIC

- DP - DBL ACTING NBR/STEEL PISTON CUP w/CUSHION - METRIC

- CB - DOUBLE ACTING NBR/STEEL PISTON CUP - INCH

- TDH - DBL ACTING NBR/STEEL PISTON CUP w/SPRING - METRIC

- BMP -SINGLE ACTING URETHANE PISTON CUP W/CUSHION - INCH

- PNEUMATIC SEALS

- PP - URE or NBR PNEUMATIC CUSHION SEAL - METRIC

- EL - URE or NBR COMBO PNEUMATIC ROD SEAL/WIPER - METRIC

- EM - URETHANE COMBO PNEUMATIC ROD SEAL/WIPER - METRIC

- E9 - NBR/MTL COMBO PNEUMATIC ROD SEAL/WIPER - METRIC

- E8 - NBR/URE COMBO PNEUMATIC ROD SEAL/WIPER - METRIC

- EU - URETHANE COMBO PNEUMATIC ROD SEAL/WIPER - METRIC

- PDU - NBR COMBINATION PNEUMATIC ROD SEAL/WIPER - METRIC

- PSD - NITRILE PNEUMATIC PISTON SEAL - METRIC

- PPD - NITRILE PNEUMATIC PISTON SEAL - METRIC

- PZ - NITRILE PNEUMATIC PISTON SEAL - METRIC

- KSP - NITRILE PNEUMATIC PISTON SEAL - METRIC

- Z8 - URE or NBR PNEUMATIC PISTON U-CUP - METRIC

- E4 - URE or NBR PNEUMATIC PISTON U-CUP

- O RINGS

- O-RINGS - 568 DASH SIZE N70,N90,V75,HN70,S70,P90 - INCH

- O-RINGS - BOSS FITTING STANDARD SIZE N70,N90,V75 - INCH

- SQUARE & O-RING N70 CORD STOCK - INCH & METRIC

- O-RINGS - JIS, EURO, N70,N90,V75,HN70,S70,P90 - METRIC

- QUAD RINGS - X-CUT N70 NITRILE - INCH

- SQUARE LATHE CUT N70 NITRILE RINGS - INCH

- O-RING, FLANGE SEAL & BACK UP KITS

- O-RING ACCESSORIES & TOOLS

- BACKUP RINGS

- 8 - CONTOURED N90 NITRILE O-RING BACKUP - INCH

- MS27595 - SOLID TEFLON® O-RING BACK UP - INCH

- MS28774 - SPLIT TEFLON® O-RING BACK UP - INCH

- MS28782 - SPIRAL TEFLON® O-RING BACK UP - INCH

- MS28783 - SPIRAL TEFLON® O-RING BACK UP - INCH

- 19/51 - FLAT 95A URETHANE O-RING BACKUP - INCH

- MBH - HYTREL® U-CUP BACK UP - METRIC

- 8700 - HYTREL® U-CUP BACK UP - INCH

- BU-T - PTFE U-CUP BACK UP - INCH

- BU-N - NYLON U-CUP BACK UP - INCH

- MBN - NYLON U-CUP BACK UP - METRIC

- MBT - SOLID TEFLON® U-CUP BACK UP - METRIC

- MB - MODULAR URETHANE U-CUP BACK UP - INCH

- BU-VEG - VEGETABLE FIBER GASKET END CAP SEAL - INCH

- WEAR RINGS / GUIDE BEARINGS

- KZT - BTFE ANGLE CUT WEARBAND w/OIL GROOVE - METRIC

- MDU - SPLIT TFE/BRONZE/STEEL ROD BUSHING - METRIC

- PSBU - SPLIT NYLON PISTON SEAL BACK UP - METRIC

- NRB - SOLID NYLON ROD BEARING - INCH

- FCB - NYLON FEMALE CENTER BEARING - INCH & METRIC

- WB - NYLON & PHENOLIC WEARBANDS - INCH

- MWB - NYLON & PHENOLIC WEARBANDS -METRIC

- WBTAPE - BTFE WEARBAND TAPE - INCH

- WBTAPE - BTFE WEARBAND TAPE - METRIC

- WBTAPE - POLY RESIN WEARBAND TAPE - INCH

- WBTAPE - POLY RESIN WEARBAND TAPE - METRIC

- WBT - T-SHAPED NYLON WEARBAND - INCH

- F1 - T-SHAPED NYLON WEARBAND - METRIC

- GEZ SPHERICAL SELF-ALIGNING BEARING - INCH & METRIC

- VEE PACKING

- VS - CHEVRON VEE PACKING SETS - INCH

- MVS - CHEVRON VEE PACKING SETS - METRIC

- VP - CHEVRON VEE COMPONENTS FAB/NBR,HYTREL®,NYLON- INCH

- VP - CHEVRON V COMPONENTS FAB/NBR,HYTREL®,NYLON -METRIC

- 6225 - AN HOMOGENOUS NITRILE CHEVRON VEE - INCH

- VP-VB - HOMOGENOUS NBR CHEVRON VEE - INCH & METRIC

- 6225 - AN TEFLON® CHEVRON VEE - INCH

- VP-VT - TEFLON® CHEVRON VEE - INCH

- THREAD, END CAP & FLANGE SEALS

- 600 - 1PC BONDED NBR/STEEL STAT-O-SEAL® - INCH

- 7500 - 1 PC SELF-CENTERING NBR/STEEL THREAD SEAL - INCH

- 400 - 1PC BONDED NBR/STEEL SEAL - INCH

- 400 - 1PC BONDED NBR/STEEL SEAL - METRIC

- OV - URETHANE SPLIT SAE FLANGE SEAL - METRIC

- SFS - UNIVERSAL URETHANE SPLIT SAE FLANGE SEAL - INCH

- CAT® REPL NITRILE SPLIT FLANGE D-RINGS (1P3XX) - INCH

- REPL HYDROLINE® & MILLER® PTFE END CAP SEALS - INCH

- HS - STATIC URETHANE HEAD SEAL - INCH

- DR - STATIC URETHANE HEAD SEAL - METRIC

- 3869 - NBR FLUID CONNECTOR FITTING SEAL - METRIC

- RET RING,CUSHION SEAL,CAP PLUG

- CP - PLASTIC CAP PLUG THREAD PROTECTORS - INCH

- SSR - STEEL VEE PACKING WAVE COMPRESSION SPRING - INCH

- MRT - NYLON or PHENOLIC CUSHION SEAL - METRIC

- V6 - PNEUMATIC URETHANE CUSHION SEAL - INCH

- 1300 - INTERNAL STEEL TRUARC® RETAINING RING - INCH

- 1400 - EXTERNAL STEEL TRUARC® RETAINING RING - INCH

- HLR - STEEL HOOK LOCK RETAINING RING - INCH

- RR - INTERNAL STEEL SPIRAL RETAINING RING - INCH

- RSI - ROUND STEEL INTERNAL RETAINING RING - INCH

- RS - EXTERNAL STEEL SPIRAL RETAINING RING - INCH

- RSE - ROUND STEEL EXTERNAL RETAINING RING - INCH

- AR - RSE U-CUP RETAINING RING - METRIC

- MNR - NYLON MAILHOT® REPLACEMENT RETAINING RING

- TELESCOPIC CYLINDER PARTS/KITS

- JOHNSON® TELESCOPIC REPLACEMENT PARTS & KITS

- COMMERCIAL/PARKER® REPLACEMENT PARTS & KITS

- CUSTOM HOIST® REPLACEMENT PARTS & KITS

- HYCO® TELESCOPIC REPLACEMENT PARTS & KITS

- HYVA® TELESCOPIC REPLACEMENT PARTS & KITS

- WARD® TELESCOPIC REPLACEMENT PARTS & KITS

- GALION® TELESCOPIC REPLACEMENT PARTS & KITS

- PERFECTION® TELESCOPIC REPLACEMENT PARTS & KITS

| Please enter search criteria or click show all |

We are officially back to same-day shipping. Thank you for your patience and understanding.

-

PARKER® STANDARD MOLYTHANE LOADED LIP SEAL POLYPAKS®

PARKER® STANDARD MOLYTHANE LOADED LIP SEAL POLYPAKS®

-

PARKER® DEEP MOLYTHANE LOADED LIP SEAL POLYPAKS®

PARKER® DEEP MOLYTHANE LOADED LIP SEAL POLYPAKS®

-

PARKER® BEVELED LIP MOLYTHANE LOADED LIP SEAL POLYPAKS®

PARKER® BEVELED LIP MOLYTHANE LOADED LIP SEAL POLYPAKS®

-

PARKER® MOLYTHANE PIP(PRESSURE INVERTING PEDESTAL) RING

PARKER® MOLYTHANE PIP(PRESSURE INVERTING PEDESTAL) RING

-

PARKER® STANDARD MOLYTHANE UR NON-SYMMETRICAL ROD U-CUP

PARKER® STANDARD MOLYTHANE UR NON-SYMMETRICAL ROD U-CUP

-

PARKER® HI-TEMPERATURE DOUBLE LIP 4300 BT ROD U-CUPS

PARKER® HI-TEMPERATURE DOUBLE LIP 4300 BT ROD U-CUPS

-

PARKER® SYMMETRICAL MOLYTHANE US ROD or PISTON U-CUPS

PARKER® SYMMETRICAL MOLYTHANE US ROD or PISTON U-CUPS

-

PARKER® STANDARD MOLYTHANE NON-SYMMETRICAL PISTON U-CUP

PARKER® STANDARD MOLYTHANE NON-SYMMETRICAL PISTON U-CUP

-

PARKER® PSP STYLE 2Pc URETHANE/NBR PISTON SEAL ASSEMBLY

PARKER® PSP STYLE 2Pc URETHANE/NBR PISTON SEAL ASSEMBLY

-

PARKER® PSP-A 2Pc URETHANE/NBR PISTON SEAL ASSEMBLY

PARKER® PSP-A 2Pc URETHANE/NBR PISTON SEAL ASSEMBLY

-

PARKER® STANDARD MOLYTHANE CS PISTON CUP

PARKER® STANDARD MOLYTHANE CS PISTON CUP

-

PARKER® THIN LIP MOLYTHANE CT PISTON CUP

PARKER® THIN LIP MOLYTHANE CT PISTON CUP

-

PARKER® STANDARD MOLYTHANE MODULAR U-CUP BACK UPS

PARKER® STANDARD MOLYTHANE MODULAR U-CUP BACK UPS

PARKER® STANDARD MOLYTHANE LOADED LIP SEAL POLYPAKS®

Parker® Standard PolyPak® is a squeeze seal with a symmetrical profile for use in either rod or piston applications. The standard Molythane® shell provides high wear resistance and the O-ring energizer functions as a spring to maintain sealing contact under low pressure. The Standard PolyPak® utilizes a straight cut scraper lip design formed by a precision trimming process. The scraper edge wipes both fluid film and contamination away from the seal. A wide selection of sizes and alternate compounds allow this profile to match up with many hydraulic applications. The Standard PolyPak® is an economical choice as a stand alone rod or piston seal. With less squeeze force than the Deep or Type B profiles, the Standard PolyPak® can be installed back-to back, in separate glands, for bi-directional sealing. To protect against pressure trapping, it is recommended that the O-ring be removed from the Standard PolyPak® facing the lower pressure side of the application.

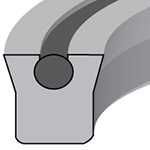

PARKER® DEEP MOLYTHANE LOADED LIP SEAL POLYPAKS®

Parker® Deep PolyPak® is a squeeze seal with a symmetrical profile for use in either rod or piston applications. Its rectangular shape ensures stability in the gland. The standard Molythane® shell provides high wear resistance and the O-ring energizer functions as a spring to maintain sealing contact under low pressure or vacuum applications. The Deep PolyPak® straight cut scraper lip design cuts fluid film and moves contamination away from the seal. The sharp edge of the lip is formed by a precision knife trimming process. A wide selection of sizes and alternate compounds allow this profile to match up with many hydraulic applications. The Deep PolyPak® is an economical choice as a stand alone rod or piston seal. Dual Deep PolyPak® seals should not be installed back to back in bi-directional piston applications as a pressure trap between the seals may occur.

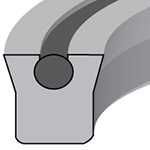

PARKER® BEVELED LIP MOLYTHANE LOADED LIP SEAL POLYPAKS®

Type B PolyPak® is a squeeze seal with a symmetrical profile for use rod applications. The rectangular shape of its cross section ensures stability in the gland. The standard Molythane® shell provides high wear resistance and the O-ring energizer functions as a spring to maintain sealing contact under low pressure or vacuum applications. The beveled lip design of the seal is excellent for cutting fluid film and is formed by a precision knife trimming process. A wide selection of sizes and alternate compounds allow this profile to match up with many hydraulic applications. The Type B PolyPak® is an economical choice as a stand-alone seal or can be used in tandem with a buffer seal. Dual Type B PolyPak® seals should not be installed back-to-back in bi-directional pressure applications, as a pressure trap between the seals may occur. Instead, for bi-directional piston sealing, incorporate a PIP Ring®

PARKER® MOLYTHANE PIP(PRESSURE INVERTING PEDESTAL) RING

The Parker® PIP Ring® profile combines a Pressure Inverting Pedestal with a Type B PolyPak® to provide excellent, bi-directional piston sealing in hydraulic applications. The PIP Ring conforms to the beveled sealing lips of the Type B PolyPak to provide extrusion resistance when pressure is applied to the heel side of the seal. The PIP Ring profile requires only a single seal groove for installation. This eliminates the use of two PolyPak seals on the piston to save space and increase bearing length. Note: The PIP Ring profile may be purchased as an assembly (Type B PolyPak and PIP Ring) or separately as a PIP Ring only. If purchasing as an assembly, the standard material is a 4615 Type B PolyPak with 4617 PIP Ring. If you desire alternate material combinations, please order the PIP Ring and Type B PolyPak separately.

PARKER® STANDARD MOLYTHANE UR NON-SYMMETRICAL ROD U-CUP

The UR profile is a non-symmetrical, hydraulic cylinder rod seal. The knife trimmed, beveled lip faces the rod to provide enhanced low to high pressure sealing and wiping action. The UR profile is an economical choice, available in Parker's® wear- and extrusion-resistant Molythane® compound.

PARKER® HI-TEMPERATURE DOUBLE LIP 4300 BT ROD U-CUPS

The BT profile is a non-symmetrical design for use in hydraulic rod sealing applications. Using Finite Element Analysis, the BT profile was designed to provide improved sealing performance and stability in the gland. A knife trimming process is used to form the beveled lip which is best for removing fluid from the rod. By design, the BT profile has a more robust primary sealing lip than the BS profile and the stabilizing lip is located at the base of the heel. The standard compound for the BT profile is Parker's® proprietary Resilon® polyurethane 4300 compound. The BT profile provides long life, extrusion resistance, low compression set, shock load resistance and increased sealing performance at zero pressure. The BT profile is designed for use as a stand alone rod seal or for use with the BR or OD profile buffer seals for more critical sealing applications.

PARKER® SYMMETRICAL MOLYTHANE US ROD or PISTON U-CUPS

The Parker® US profile is a symmetrical, beveled lip u-cup designed for use in hydraulic cylinder applications. The symmetrical shape allows interchangeability between rod and piston applications. A precision knife trimming process is utilized to create the beveled sealing lips. This ensures that the inside and outside diameter sealing edges provide excellent fluid wiping action. The US profile is a single acting seal. Two seals can be installed back to back, in separate grooves, to seal dual acting pistons without pressure trapping fluid between the seals. The US profile is an economical choice, available in Parker's® wear resistant and extrusion resistant Molythane® compound.

PARKER® STANDARD MOLYTHANE NON-SYMMETRICAL PISTON U-CUP

The UP profile is a non-symmetrical, hydraulic piston seal. The knife trimmed, beveled lip faces the bore to provide enhanced low to high pressure sealing and wiping action. The UP profile is a uni-directional seal. Two UP seals can be used, back to back, in separate grooves to provide bi-directional pressure sealing. The UP profile is an economical choice, available in Parker's® wear resistant and extrusion resistant Molythane® compound.

PARKER® PSP STYLE 2Pc URETHANE/NBR PISTON SEAL ASSEMBLY

The PSP profile is a squeeze type, bi-directional piston seal for use in light to medium duty hydraulic applications. Available from proprietary Parker polyurethanes, the PSP offers low friction, abrasion and extrusion resistance. The nitrile elastomer energizer ensures resistance to compression set to increase seal life. The PSP profile's geometry provides a fluid reservoir between the two sealing lips which holds system fluid, resulting in reduced breakaway and running friction. Designed to retrofit grooves for a single O-ring or an O-ring with two back-ups, the PSP profile is easy to install and resists rolling and twisting in long stroke applications.

PARKER® PSP-A 2Pc URETHANE/NBR PISTON SEAL ASSEMBLY

The PSP-A profile is a squeeze type, new style bi-directional piston seal for use in light to medium duty hydraulic applications. Available from proprietary Parker polyurethanes, the PSP offers low friction, abrasion and extrusion resistance. The nitrile elastomer energizer ensures resistance to compression set to increase seal life. The PSP-A profile's geometry provides a fluid reservoir between the two sealing lips which holds system fluid, resulting in reduced breakaway and running friction. Designed to retrofit grooves for a single O-ring or an O-ring with two back-ups, the PSP-A profile is easy to install and resists rolling and twisting in long stroke applications.

PARKER® STANDARD MOLYTHANE CS PISTON CUP

CS type piston cups are molded of Molythane and are recommended for hydraulic applications.

PARKER® THIN LIP MOLYTHANE CT PISTON CUP

These piston cups are molded of Molythane and are recommended for hydraulic applications.

PARKER® STANDARD MOLYTHANE MODULAR U-CUP BACK UPS

Modular back-ups, MB profile, are specifically designed to complement the PolyPak® profiles. To help make the selection and ordering of the correct part number for the MB profile easy and efficient, the part numbering system used is very similar to that of the PolyPak. By formulating high modulus blends of Molythane® (4617) and Polymyte® (4652), Parker® has ensured that MB back-ups can be used with either type of base sealing material while maintaining the expected temperature range and fluid compatibility. The robust design ensures pressure ratings up to 10,000 psi are met.

Allegheny York Hydraulic Seals

Allegheny York Hydraulic Seals and Pneumatic Seals

Allegheny York offers all the necessary elements for virtually every hydraulic seal and hydraulic cylinder seal application. Big or small, we welcome National Suppliers, wholesalers, MRO, OEM, government, repair shops, and retailers. Our products include High quality Hydraulic Seals. These include Wipers, Rod Seals, Piston Seals, Wear Rings, O-Rings, Back-up Rings, U-Seals, Rod Seals, Piston Seals, Wear Rings, Buffer Seals, Vee Packing, Retainer Rings, Wiper Rings, Oil Seals, Cushion Seals, Custom Machined Seals, Pneumatic Seals, and Aftermarket Cylinder Seal Kits for the fluid power industry.

With a large online variety of high performance seals in thousands of sizes. Whether it is small or large diameter, low or high pressure, reciprocating or rotary motion, dynamic or static sealing, a suitable product for your application is available.

We deliver seal solutions to meet the needs of every customer in a vast array of industries including: heavy industrial, mining, manufacturing, high-tech, medical, military, precious metals, natural resource extraction, processing equipment, and many more. With our material knowledge, technological capabilities, and applications experience, Allegheny York is able to offer customers both tailor-made solutions and complete sealing systems of the highest quality.

Our team knows seals—we guarantee a reliable, informed contact every time you call. We give you the advantage with competitive pricing and quick order turnaround for Any Conceivable Application.

Allegheny York specializes in custom engineered sealing solutions for numerous industries. Our innovative machine technology and experienced engineering team enable us to produce an unlimited number of seal profiles in sizes up to 38 inches in diameter.

With turnaround time as short as same day, our custom machined products meet the highest quality standards. Production systems are fast and efficient, keeping manufacturing and lead times to a minimum. Request a quote for custom machined seals.

Our advanced machining centers allow you to choose from 170 standard profiles or unlimited custom designs. We manufacture seals up to 38 inches. Custom designs and unique sizes are available in a variety of materials.

Allegheny York stocks a substantial selection of hydraulic and pneumatic seals.These seals prevent fluid leakage in hydraulic systems. We purchase quality inventory and meet stringent industry standards to provide the best available products. With one of most extensive inventories in the country, we are confident we can provide the seals you need. Standard and metric sizes are available in a variety of materials, ranging from urethanes and elastomers to engineered plastics.

We consistently source new and improved product lines, increasing our inventory to satisfy demand. We enjoy the challenge of providing solutions to the most difficult seal applications.

Allegheny York offers a wide range of aftermarket seal kits. Our knowledgeable technicians will assemble complete kits based on a manufacturer serial or model numbers. If these identifying numbers are not available, we can reverse engineer a kit product to provide the parts you need.

Since we maintain a large inventory of major industrial and heavy equipment manufacturers, turnaround time for kit orders is as short as one day. All kits meet or exceed OEM specifications.

Allegheny York’s Industrial Seals Catalog makes ordering parts easy. The catalog features tens of thousands of parts with a seal profile index that will help you easily identify the seals you need. Profile sections include all the necessary material and engineering information as well as easily identifiable sizing. Our catalog is your easy to use resource for part ordering.

Cage Code: 3F317