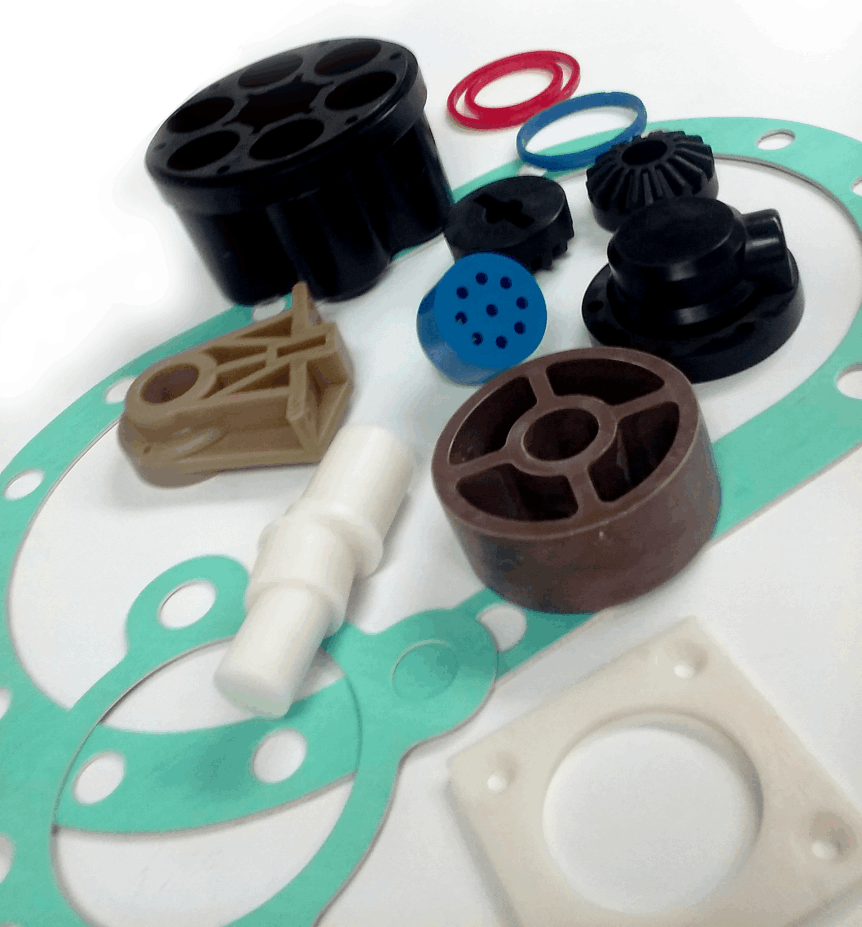

Custom Made Seals on Demand

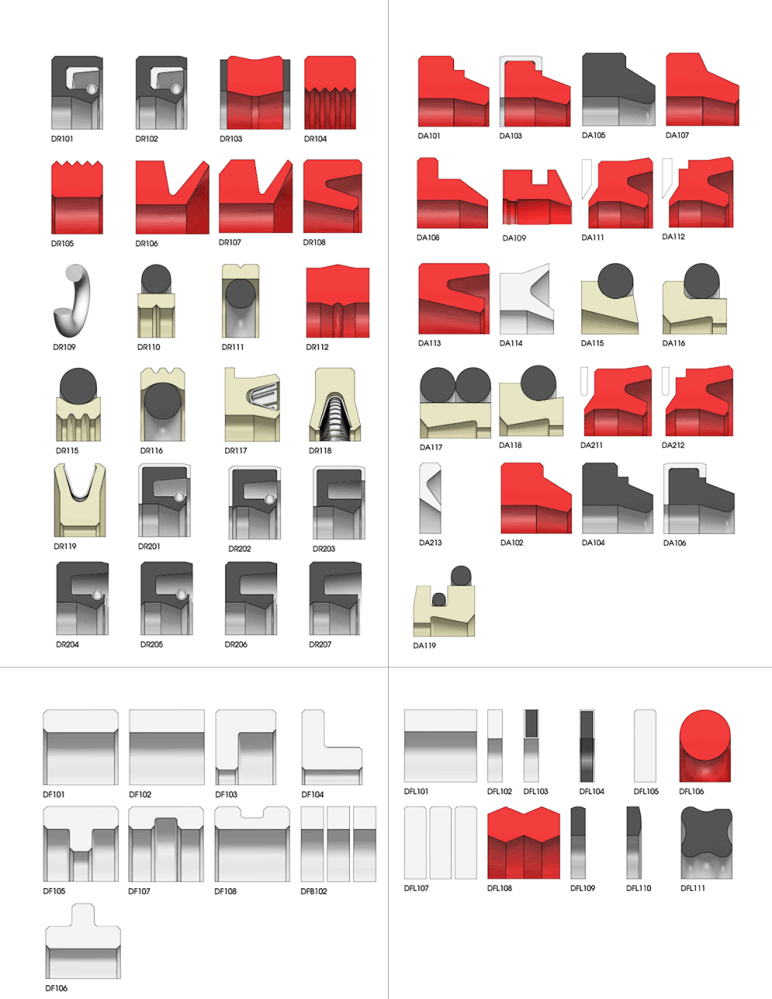

Konsep Co. will manufacture custom sealing products to meet your demands using advanced rapid prototyping technology. Parts can be made from over 100 profiles for same-day delivery using our extensive inventory of available materials. Our Engineering team will design the part to fit your requirements and supply a drawing and quotation for your approval prior to manufacturing.

Size Capabilities

Inch (5/16" I.D. to 23-1/2" O.D.)

Metric (8 mm I.D. to 600mm O.D)

STANDARD MATERIALS FOR MACHINED PARTS