Chat Widget

Chat Widget

S2K Commerce - Products Dropdown

S2K Commerce - Products Dropdown

S2K Commerce - Shopping Cart

S2K Commerce - Shopping Cart

Google Tag Manager Code

Google Tag Manager Code

Homepage Banner Slideshow

Homepage Banner Slideshow

icon menu bar

icon menu bar

Sale Header

Sale Header

S2K Commerce - Order Entry

S2K Commerce - Order Entry

Piston seals are intended to prevent leakage past the piston and therefore maximize the efficiency of a system.

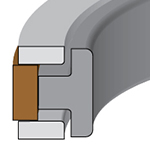

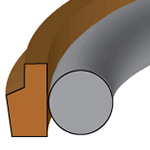

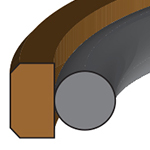

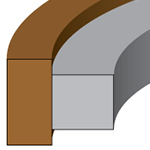

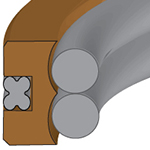

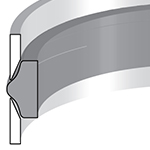

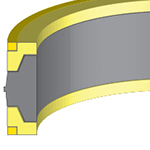

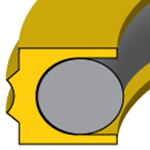

12 - 1PC 2 DURO URETHANE UNIRING PISTON SEAL - INCH

Uni-rings seals are a one pc. double acting piston seal made from 2 different durometers of urethane bonded together. The outer surface is impregnated with molybdenum disulfide (for decreasing friction) and contains a groove to hold lubricant. Some of these seals will retrofit into T-seal and wide base T-seal grooves.

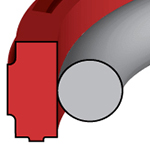

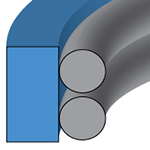

4PE/4PV - 4 PC BTFE or URE/NBR/NYLON PISTON SEAL - INCH

These heavy-duty seals are designed to withstand higher pressures and shock loads with less damage to the seal. T-seal principles are utilized with back-ups being used to protect the seal from contaminants. The compact design allows use of shorter pistons and larger bearing surfaces. They are commonly found in Caterpillar® cylinders. Temperature: -40° to 225°F Pressure: 0 to 6,000 PSI

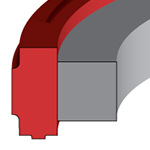

4PMM - 4 PC BTFE/NBR/NYLON PISTON SEAL - METRIC

These heavy-duty seals are designed to withstand higher pressures and shock loads with less damage to the seal. T-seal principles are utilized with back-ups being used to protect the seal from contaminants. The compact design allows use of shorter pistons and larger bearing surfaces. They are commonly found in Caterpillar® cylinders. Temperature: -40° to 225°F Pressure: 0 to 6,000 PSI

4PT - 4 PC BTFE/NBR/NYLON CAT®TYPE PISTON SEAL - INCH

These heavy-duty seals are designed to withstand higher pressures and shock loads with less damage to the seal. T-seal principles are utilized with back-ups being used to protect the seal from contaminants. The compact design allows use of shorter pistons and larger bearing surfaces. They are commonly found in Caterpillar® cylinders. Temperature: -40° to 225°F Pressure: 0 to 6,000 PSI

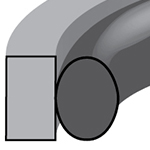

714 - 2 PC STEPCUT NYLON PISTON SEAL w/SQR ENGZR - INCH

714 style piston seals are step cut, and are made from glass filled polyamide. The rectangular energizer is a molded 70 durometer Shore A nitrile. They are primarily designed for heavy duty, double acting hydraulic applications. The sealing set is capable of passing a port and can be used up to 10,000 psi (680 bar) with proper fitting. It's advantages are small profile, resistant to shock loads, low breakout and running friction, even after lengthy standstill under high pressures. They install easily due to the split outer sealing ring and offer high abrasion and extrusion resistance at high pressures and large clearance gaps. Temperature: -40° to 250°F Pressure: 0 to 7,250 PSI

914 - 2 PC STEPCUT NYLON PISTON SEAL w/OVAL ENGZR -INCH

Genuine Chem-Cast® piston rings consist of a moly/glass-filled nylon step cut outer ring with a precision milled joint, together with a carboxylated nitrile 90 durometer oval expander ring. The expander ring is designed so as not to pinch between the joint of the outer ring during installation. These rings will pass a small port with no problem and can handle large diametrical clearances. It is the seal of choice for super-heavy duty applications. Many OEMs have adopted this seal due to its superior sealing ability, wear resistance, and port passing capabilities. Do not cut rings down for any reason. Temperature: -40° to 250°F Pressure: 0 to 10,000 PSI

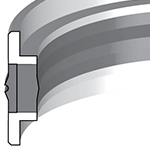

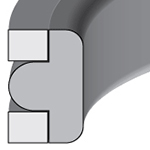

AS2 - 2 PC STEPPED BTFE/NBR PISTON BUFFER SEAL - INCH

Stepped seals are used to buffer pressure spikes from the primary piston seal, and are sometimes used in tandem. Combined with an unloaded u-cup, pressure builds between the step seal and primary seal and helps load the u-cup. Seals are machined from bronze filled Teflon®. Expanders are 70 durometer high memory nitrile, and are also available in Viton. Temperature: -40°F to 225°F Pressure: 0 to 3500 psi

AS2 -2 PC STEPPED BTFE/NBR PISTON BUFFER SEAL - METRIC

Stepped seals are used to buffer pressure spikes from the primary piston seal, and are sometimes used in tandem. Combined with an unloaded u-cup, pressure builds between the step seal and primary seal and helps load the u-cup. Seals are machined from bronze filled Teflon®. Expanders are 70 durometer high memory nitrile, and are also available in Viton. Temperature: -40°F to 225°F Pressure: 0 to 3500 psi

CAT® 2PC REP NYLON PISTON SEAL w/OVAL NBR EXPNDR - MM

These 2 piece Cat® style outer sealing rings are step cut, and are made from glass-filled polyamide. The rectangular energizer is a molded 70 durometer Shore A nitrile. They are primarily designed for heavy duty, double acting hydraulic applications. The sealing set is capable of passing a port and can be used up to 10,000 psi (680 bar) with proper fitting. Its advantages are small profile, resistant to shock loads, and low breakout and running friction even after lengthy standstill under high pressures. They install easily due to the split outer sealing ring and offer high abrasion and extrusion resistance at high pressures and large clearance gaps.

AS5/6/PSP-2 PC RECTANGULAR PU®/NBR PISTON SEAL - METRIC

These compact seal assemblies are molded from a specially blended urethane material and include a 70 durometer nitrile expander. They are interchangeable with many popular TFE piston seal grooves and offer easier installation and better resistance to cold flow and extrusion. Temperature: -40° to 230°F Pressure: 0 to 5,000 PSI Material: Urethane/nitrile

AS600 - 2 PC RECTANGULAR HYTREL®/NBR PISTON SEAL - INCH

These compact seal assemblies are molded from a specially blended hytrel® material and include a 70 durometer nitrile O-ring expander. They are interchangeable with the AS900 TFE piston seal grooves and offer easier installation and better resistance to cold flow and extrusion. Temperature: -40° to 225°F Pressure: 0 to 5,000 PSI

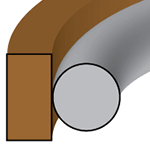

AS7 - 2 PC BTFE/NBR HEAVY DUTY PISTON SEAL - INCH

Our AS7 series piston seals are machined from bronze filled TFE for the most severe applications. Standard expander rings on this series piston seal are round cross section high memory 70 durometer nitrile; however, Viton expanders are available. Consult sales for pricing and delivery of special compounds. Temperature: -40° to 225°F Pressure: 0 to5,000 PSI

AS7 - 2 PC BTFE/NBR HEAVY DUTY PISTON SEAL - METRIC

Our AS7 series piston seals are machined from bronze filled TFE for the most severe applications. Standard expander rings on this series piston seal are round cross section high memory 70 durometer nitrile; however, Viton expanders are available. Consult sales for pricing and delivery of special compounds. Temperature: -40° to 225°F Pressure: 0 to5,000 PSI

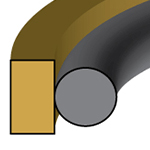

AS700 - 2 PC RECTANGULAR GTFE/NBR PISTON SEAL - INCH

AS700 style rectangular piston seal assemblies are manufactured from glass filled TFE and include a 70 durometer nitrile O-ring energizer. This medium duty seal is found in many forklift and agricultural applications and can be considered in applications requiring a compact seal and ease of installation. Temperature: -40° to 225°F Pressure: 0to 3,000 PSI

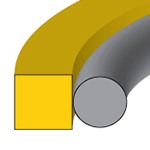

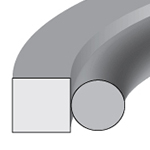

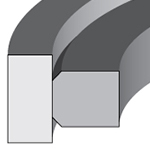

AS800 - 2 PC TFE/NBR PISTON SEAL - INCH

AS800 style square piston seal assemblies are made from glass filled TFE and include an O-ring energizer. This popular medium duty assembly assures dependable service to a wide variety of sealing applications from rotary swivels to reciprocating cylinders. Temperature: -40° to 225°F Pressure: 0 to 3,000 PSI

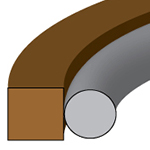

AS800B - 2 PC BTFE/NBR PISTON SEAL - INCH

AS800-B style square piston seal assemblies are made from bronze filled TFE and include an O-ring energizer. This popular medium to heavy duty assembly assures dependable service to a reciprocating cylinders. Temperature: -40° to 225°F Pressure: 0 to 3,000 PSI

AS800P - 2 PC SQUARE URETHANE/NBR PISTON SEAL - INCH

AS800P square piston seal assemblies are made from polyurethane and include an O-ring energizer. They install easier than Teflon® and because they snap back into the groove they require no re-sizing. The wear properties are good due to the high durometer of urethane used. Temperature: -65° to 220°F Pressure: 0 to 5,000 PSI

AS880 - 3PC GTFE/NBR PISTON SEAL w/2 O-RINGS - INCH

AS880 style rectangular piston seal assemblies are basically double wide AS800 seals. They are manufactured from glass filled TFE and include two 70 durometer nitrile O-ring energizers. They are used in some mobile hydraulic applications including drilling equipment and boom trucks. Temperature: -40° to 225°F Pressure: 0 to 3,000 PSI

AS9 - SPECIAL SIZE 2 PC CTFE/NBR PISTON SEAL - INCH

These rectangular piston seal assemblies are manufactured from a rugged bronze filled TFE material and include a 70 durometer square cut or O-ring energizer. The AS930 series are used in many trash equipment cylinders and the AS960 series are found in many logging and construction equipment applications. Temperature: -40° to 225°F Pressure: 0 to 5,000 PSI

AS900 - 2 PC RECTANGULAR GTFE/NBR PISTON SEAL - INCH

AS900 style rectangular piston seal assemblies are supplied with 70 durometer nitrile square cut energizers and glass filled Teflon® outer rings for extra heavy duty applications and larger clearance gaps. AS900 style seals provide many cycles of drift-free service to medium and heavy duty cylinder applications. Temperature: -40° to 225°F Pressure: 0 to 3,000 PSI Material: 40% Glass-filled Teflon®

AS900B - 2 PC RECTANGULAR BTFE/NBR PISTON SEAL - INCH

AS900 style rectangular piston seal assemblies are supplied with 70 durometer nitrile square cut energizers and glass filled Teflon® outer rings for extra heavy duty applications and larger clearance gaps. AS900 style seals provide many cycles of drift-free service to medium and heavy duty cylinder applications. Temperature: -40° to 225°F Pressure: 0 to 3,000 PSI Material: 40% Glass-filled Teflon®

AS980 - CAT® REPL 2 PC GTFE/NBR HEAVY DUTY TFE - INCH

AS980 rectangular piston seal assemblies are manufactured from a custom blended glass/moly reinforced TFE and include a rectangular shaped nitrile lathe cut expander. These rugged seals are replacements for those used in Caterpillar® equipment and auxiliary items used on construction equipment. Temperature: -40° to 225°F Pressure: 0 to 3,000 PSI

AS990 - 2 PC RECTANGULAR BTFE/NBR PISTON SEAL - METRIC

These rectangular bronze filled TFE piston seal assemblies include a 70 durometer nitrile O-ring energizer. These heavy duty seals can be supplied with Viton expanders. Consult sales office for price and availability. Temperature: -40° to 225°F Pressure: 0 to 5,000 PSI

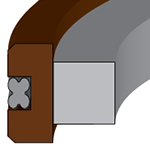

ASQ - 3 PC BTFE/QUAD W/ORING PISTON SEAL W/ORING - INCH

This piston seal is a 3 piece assembly consisting of a nitrile energizer, a bronze-filled Teflon® grooved cap ring, with a nitrile quad ring inserted in the groove. The ASQ seal combines low friction and positive sealing. They are often found in load holding applications where drift is unacceptable. Other configurations and materials are available. Temperature: -40° to 225°F Pressure: 0 to 5,000 PSI

ASQ - 3 PC BTFE/QUAD W/ORING PISTON SEAL W/ORING-METRIC

This piston seal is a 3 piece assembly consisting of a nitrile energizer, a bronze-filled Teflon® grooved cap ring, with a nitrile quad ring inserted in the groove. The ASQ seal combines low friction and positive sealing. They are often found in load holding applications where drift is unacceptable. Other configurations and materials are available. Temperature: -40° to 225°F Pressure: 0 to 5,000 PSI

ASQ5 - 4PC BTFE/QUAD PISTON SEAL w/ 2 NBR EXPANDERS

This piston seal is a 4 piece assembly consisting of 2 nitrile energizers, a bronze-filled Teflon grooved cap ring, with a nitrile quad ring inserted in the groove. The ASQ5 seal combines low friction and positive sealing. They are often found in load holding applications where drift is unacceptable. Other configurations and materials are available. Temperature: -40° to 225°F Pressure: 0 to 5,000 PSI

CAT® 2PC REP NYLON PISTON SEAL w/OVAL NBR EXPNDR - INCH

These 2 piece Cat® style outer sealing rings are step cut, and are made from glass-filled polyamide. The rectangular energizer is a molded 70 durometer Shore A nitrile. They are primarily designed for heavy duty, double acting hydraulic applications. The sealing set is capable of passing a port and can be used up to 10,000 psi (680 bar) with proper fitting. Its advantages are small profile, resistant to shock loads, and low breakout and running friction even after lengthy standstill under high pressures. They install easily due to the split outer sealing ring and offer high abrasion and extrusion resistance at high pressures and large clearance gaps.

CAT® 2PC REP NYLON PISTON SEAL w/OVAL NBR EXPNDR - MM

These 2 piece Cat® style outer sealing rings are step cut, and are made from glass-filled polyamide. The rectangular energizer is a molded 70 durometer Shore A nitrile. They are primarily designed for heavy duty, double acting hydraulic applications. The sealing set is capable of passing a port and can be used up to 10,000 psi (680 bar) with proper fitting. Its advantages are small profile, resistant to shock loads, and low breakout and running friction even after lengthy standstill under high pressures. They install easily due to the split outer sealing ring and offer high abrasion and extrusion resistance at high pressures and large clearance gaps.

CP - 2 PC RECTANGULAR URE®/NBR PISTON CROWN SEAL - INCH

Crown seals are bi-directional squeeze type piston seals used as direct substitutes for O-rings and T-seals. Material: PU/NBR. Temp: 65 to 220° F

DAS - 5 PC NITRILE/NYLON/POM PISTON SEAL - INCH

Compact seal design allows for the bearings to be as close as possible to the seal for excellent protection against contaminants and assures concentricity between piston and bore. Piston seals in this section may be different than design pictured. Temperature: -22° to 212°F Pressure: 0 to 5,800 PS

DAS - 5 PC NITRILE/NYLON/POM PISTON SEAL - METRIC

Compact seal design allows for the bearings to be as close as possible to the seal for excellent protection against contaminants and assures concentricity between piston and bore. Piston seals in this section may be different than design pictured. Temperature: -22° to 212°F Pressure: 0 to 5,800 PS

DS - 3PC NBR w/POM BEARINGS DELTA PISTON SEAL - INCH

The DS seal is a 3 piece double acting piston seal made of an elastomeric nitrile rubber sealing element with 2 special profile thermoplastic guide rings. It offers an economical solution and simple installation in small cross sections and one piece pistons. Min Oils Temperature: -20°F to +220°F HFA/HBF Temperature: -40°F to +140°F HFC Temperature: -20°Fto +140°F Pressure: PSI 2100

DSM - 3PC NBR w/POM BEARINGS DELTA PISTON SEAL - METRIC

The DS seal is a 3 piece double acting piston seal made of an elastomeric nitrile rubber sealing element with 2 special profile thermoplastic guide rings. It offers an economical solution and simple installation in small cross sections and one piece pistons. Min Oils Temperature: -20°F to +220°F HFA/HBF Temperature: -40°F to +140°F HFC Temperature: -20°Fto +140°F Pressure: PSI 2100

DSM - 5 PC NITRILE/NYLON/POM PISTON SEAL - METRIC

The DSM series 5 piece piston seal is a compact seal designed for heavy duty double-acting cylinders. It consists of one multiple lip elastomeric nitrile rubber sealing element, two polyester elastomer backup rings to prevent extrusion, and two L-shaped thermoplastic guide rings that help to center the piston within the bore. This is a great high-pressure seal with low friction. Pressure: 10,000 psi

GD1KK - 6PC NITRILE/NYLON/POM PISTON SEAL - METRIC

These 6 pc. piston seals are commonly found in Trojan Loader cylinders made by Hunger® Hydraulics. The outer sealing ring is made from bronze-filled Teflon® and the expander ring is made from 80 Duro Nitrile. The seal assembly also includes 2 backup rings and 2 slotted nylon bearings Temperature: -40° to 225°F Pressure: 0 to 4,350 PSI

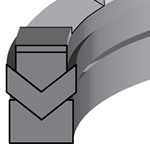

M4 - 3PC FAB/NBR/NYLON PISTON VEE SET SEAL - METRIC

The M4 series piston seal is a 3 piece single-acting sealing set which consists of a rock-hard fabric and rubber female, a fabric-reinforced center ring, and a thermoplastic male adapter. This seal requires a 2 pc. Piston for easy installation, and works well with poor surface finishes. Temperature: -22° to 212°F

MDL - 3PC DOUBLE ACTING NBR/POM PISTON SEAL - METRIC

Series MDL is a 3 pc. double-acting compact piston seal consisting of one fabric-reinforced elastomeric sealing element and two thermoplastic guide/backup rings. Product advantages are low friction, improved abrasion resistance, good dynamic and static sealing, and long service life. Min Oils Temperature: -20° F to +220° F HFA/HBF Temperature:-40° F to +140° F HFC Temperature: -20° F to +140° F Pressure: PSI 5800

MHM - JCB® REPL 5 PC SQUARE BACK PISTON SEAL - METRIC

This compact 5 piece piston seal is made specifically to replace JCB® and heavy duty equipment piston seals.NBR, Urethane, and POM

NO - 2PC FAB/NBR PISTON SEAL w/NYLON BACK UP - METRIC

The NO series piston seal is a 2 piece single-acting sealing set which consists of a fabric reinforced lip seal (u-cup), and a rock-hard fabric reinforced backup ring. The lip seal has an integrated support ring for stability and will discharge pressure that could build up between the seals in a double-acting cylinder. The backup ring is made from rock-hard fabric reinforced nitrile. This seal set requires a 2 pc piston. Temperature: -22° to 212°F Pressure: 0 to 7,000 PSI

OK - 2 PC STEPCUT NYLON PISTON SEAL w/SQR ENGZR -METRIC

The OK style outer sealing rings are step cut, and are made from glass-filled polyamide. The rectangular energizer is a molded 70 durometer Shore A nitrile. They are primarily designed for heavy duty, double acting hydraulic applications. The sealing set is capable of passing a port and can be used up to 10,000 psi (680 bar) with proper fitting. It's advantages are small profile, resistant to shock loads, and low breakout and running friction even after lengthy standstill under high pressures. They install easily due to the split outer sealing ring and offer high abrasion and extrusion resistance at high pressures and large clearance gaps. Temperature: -40° to 250°F Pressure: 0to 7,250 PSI

PR - CAST IRON METAL PISTON RINGS - INCH

Cast iron piston rings are used in applications requiring high temperatures, port passing capabilities or high pressure. Typical applications require at least 3 rings but are sometimes used in conjunction with TFE seals. Temperature: consult technical service Pressure: 0 to 10,000 PSI

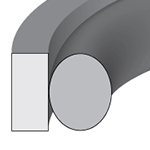

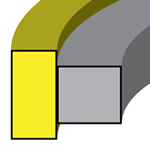

PSP - 2 PC RECTANGULAR URE®/NBR PISTON SEAL - INCH

PSP seals are bi-directional squeeze type piston seals used as direct substitutes for O-rings, T-seals and Cap seals in industrial no-back-up O-ring grooves. The unique geometry of the PSP seal design creates a fluid reservoir between the two level bi-lip sealing surfaces. This feature provides extra lubrication resulting in reduced breakaway and running friction. PSP seals are manufactured from a proprietary low friction urethane, which has excellent abrasion, tear and extrusion resistance. PSP seals provide positive, no drift sealing at a continuous service temperature range from -65 to +220 degrees F, and pressures up to 5000 psi with the recommended groove dimensions and tolerances. Temperature: -65° to 220°F Pressure: 0 to 5,000 PSI

PSP-A 2 PC NEW STYLE URE®/NBR PISTON SEAL - INCH

PSP seals are bi-directional squeeze type piston seals used as direct substitutes for O-rings, T-seals and Cap seals in industrial no-back-up O-ring grooves. The unique geometry of the PSP seal design creates a fluid reservoir between the two level bi-lip sealing surfaces. This feature provides extra lubrication resulting in reduced breakaway and running friction. PSP seals are manufactured from a proprietary low friction urethane, which has excellent abrasion, tear and extrusion resistance. PSP seals provide positive, no drift sealing at a continuous service temperature range from -65 to +220 degrees F, and pressures up to 5000 psi with the recommended groove dimensions and tolerances. Temperature: -65° to 220°F Pressure: 0 to 5,000 PSI

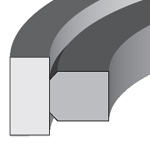

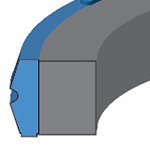

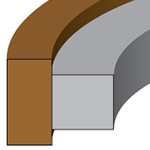

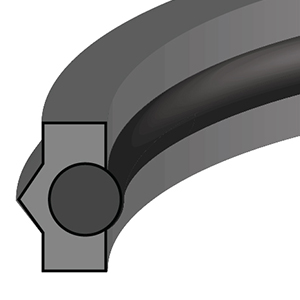

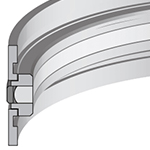

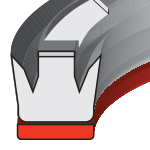

TP0 - 3 PC NITRLIE PISTON T-SEAL w/NYLON BACKUPS- INCH

Piston T-seals were originally developed to replace O-rings, and retrofit into standard commercial O-ring grooves. This development ended two serious reliability problems: 1. Extrusion through the clearance gap, and, 2. Spiral or twisting failure due to instability in their groove. T-seals back-ups are hydraulically or pneumatically driven against the dynamic surface when system pressure forces the elastomer into the space beneath the back-up. This immediate response to pressure makes them very effective wipers, keeping contaminants away from the sealing line. Standard material for our T-seals is 75 durometer nitrile with moly-filled nylon back-up rings. Other materials are available upon request. Industrial piston T-seals are also available to fit one and two back-up O-ring grooves. Please refer to Wide Base T-seals in this section. Temperature: -40° to 225°F Pressure: 0 to 5,000 PSI

TPT - WIDE BASE 3 PC NITRLIE PISTON T-SEAL - INCH

Wide Base T-seals fit into O-ring grooves designed for 1 or 2 backup rings. TPS prefix indicates 1 backup ring groove. TPT prefix indicates a 2 backup ring groove. No suffix indicates standard industrial groove. -1 suffix indicates Mil-G-5514F groove. Temperature: -40° to 225°F Pressure: 0 to 5,000 PSI

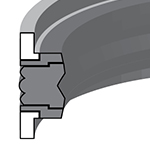

UP - STEEL w/TFE SEAL & WEARBANDS UNITIZED PISTON SEAL

This piston assembly is a single entity comprised of a piston, bearing, and seal. This simplifies building cylinders by reducing the amount of parts needed for the job. It eliminates metal to metal contact completely, ensuring longer seal life while reducing contamination.

Tag Insert

Tag Insert

Allegheny York Hydraulic Seals

Homepage Description

Homepage Description

Allegheny York Hydraulic Seals and Pneumatic Seals

Allegheny York offers all the necessary elements for virtually every hydraulic seal and hydraulic cylinder seal application. Big or small, we welcome National Suppliers, wholesalers, MRO, OEM, government, repair shops, and retailers. Our products include High quality Hydraulic Seals. These include Wipers, Rod Seals, Piston Seals, Wear Rings, O-Rings, Back-up Rings, U-Seals, Rod Seals, Piston Seals, Wear Rings, Buffer Seals, Vee Packing, Retainer Rings, Wiper Rings, Oil Seals, Cushion Seals, Custom Machined Seals, Pneumatic Seals, and Aftermarket Cylinder Seal Kits for the fluid power industry.

With a large online variety of high performance seals in thousands of sizes. Whether it is small or large diameter, low or high pressure, reciprocating or rotary motion, dynamic or static sealing, a suitable product for your application is available.

We deliver seal solutions to meet the needs of every customer in a vast array of industries including: heavy industrial, mining, manufacturing, high-tech, medical, military, precious metals, natural resource extraction, processing equipment, and many more. With our material knowledge, technological capabilities, and applications experience, Allegheny York is able to offer customers both tailor-made solutions and complete sealing systems of the highest quality.

Our team knows seals—we guarantee a reliable, informed contact every time you call. We give you the advantage with competitive pricing and quick order turnaround for Any Conceivable Application.

Allegheny York specializes in custom engineered sealing solutions for numerous industries. Our innovative machine technology and experienced engineering team enable us to produce an unlimited number of seal profiles in sizes up to 38 inches in diameter.

With turnaround time as short as same day, our custom machined products meet the highest quality standards. Production systems are fast and efficient, keeping manufacturing and lead times to a minimum. Request a quote for custom machined seals.

Our advanced machining centers allow you to choose from 170 standard profiles or unlimited custom designs. We manufacture seals up to 38 inches. Custom designs and unique sizes are available in a variety of materials.

Allegheny York stocks a substantial selection of hydraulic and pneumatic seals.These seals prevent fluid leakage in hydraulic systems. We purchase quality inventory and meet stringent industry standards to provide the best available products. With one of most extensive inventories in the country, we are confident we can provide the seals you need. Standard and metric sizes are available in a variety of materials, ranging from urethanes and elastomers to engineered plastics.

We consistently source new and improved product lines, increasing our inventory to satisfy demand. We enjoy the challenge of providing solutions to the most difficult seal applications.

Allegheny York offers a wide range of aftermarket seal kits. Our knowledgeable technicians will assemble complete kits based on a manufacturer serial or model numbers. If these identifying numbers are not available, we can reverse engineer a kit product to provide the parts you need.

Since we maintain a large inventory of major industrial and heavy equipment manufacturers, turnaround time for kit orders is as short as one day. All kits meet or exceed OEM specifications.

Allegheny York’s Industrial Seals Catalog makes ordering parts easy. The catalog features tens of thousands of parts with a seal profile index that will help you easily identify the seals you need. Profile sections include all the necessary material and engineering information as well as easily identifiable sizing. Our catalog is your easy to use resource for part ordering.

Cage Code: 3F317